Services

Our Services

Production

Prototype

Inspection

For a range of products, source inspection means fewer steps in the machining process. The customer does not have to maintain a separate Quality Control process either. The quality record of our product allows all future shipments to go “dock to stock”, straight into the customer’s parts inventory.

Reverse Engineering

Demand Pull Ordering

Design for Manufacture

JIT Manufacturing

Services | Materials

ALUMINUM

STAINLESS STEEL

BRONZE

BRASS

COPPER

PLASTICS

MIXED MATERIAL

Services | Processes

Milling – Mann Precision uses Horizontal and Vertical Milling for both prototype and production. In horizontal milling the part is typically only handled once, between the primary & secondary operations. All positioning is maintained to the accuracy of the machine tool itself. In vertical milling we design fixtures so all operations can be completed in one loading with high density part locating for maximum unattended operation.

Screw Machine – Once a screw machine is set up, it continues running until you stop it. We run our machines 24 hours a day to maximize their production time. Extra automation minimizes human involvement, so product is done in one or two operations, all without leaving the machining enclosure.

Turn/Mill – All of our turning machines are milling capable. In a turn/mill machine the rotating material is the primary axis but the machine can also use rotating (or “Live”) cutting tools, both on and off axis. Product is done in one operation, start to finish with no variation caused by handling between operations.

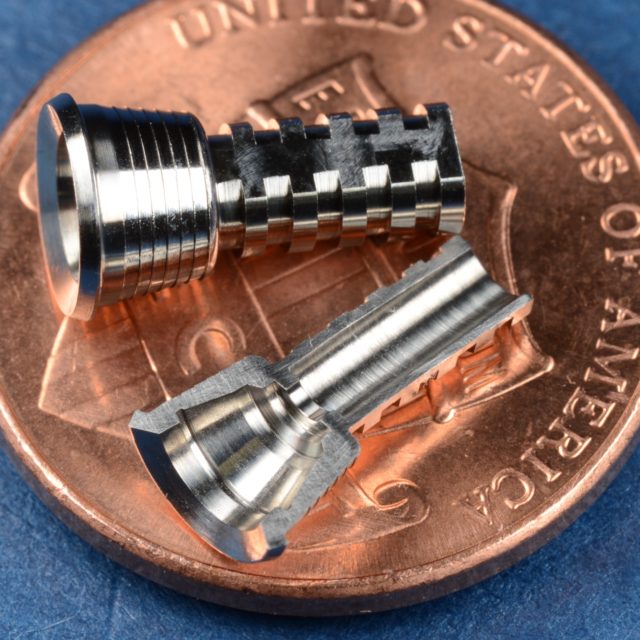

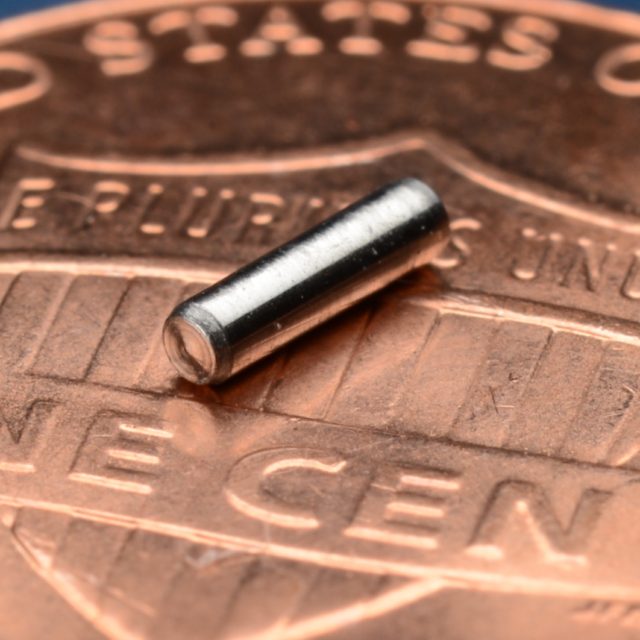

Quality

AT MANN PRECISION, INC., WE PRIDE OURSELVES ON OUR ABILITY TO PRODUCE HIGHLY ACCURATE PARTS IN PROTOTYPE OR PRODUCTION QUANTITIES WELL OVER 300,000 YEARLY. Our tooling is not hand ground as it is with many other machining outfits. When a tool or part wears, it is replaced with an absolutely identical tool or part, which results in faster changeovers and predictable product life with minimal dimensional or finish variations. In the special cases where form tooling is more productive it is precision ground by the best CNC grinders.

Our highly automated production equipment helps us control costs while increasing production precision and quality. Our hands-off CNC CMM delivers consistent repeatable results, as there is no human influence (necessary when operating manual CMM’s). We choose to rely on state-of-the-art technological automation and speed to control costs, rather than purchasing marginal equipment at a low cost. We purchase and use only the highest quality tools and equipment to produce parts and, because our production processes rely on a high level of automation, we experience consistent quality and pricing unaffected by the unpredictable dynamics of the labor market.

High Quality – Low Cost

State-of-the-art technology

Consistent repeatable results

High precision production

Predictable product life

Automated processes

Rapid changeovers

No hand grinding

Low cost factor

See our quality for yourself. Contact Us to request a parts showing, tour or consultation.

Industries served

Mann Precision, Inc. can/has worked with various industries. Parts made by us are in use all over the world.

Consumer Products

Defense

Medical

Semiconductor Equipment

Currently, most of our products are manufactured for the Consumer Goods industry. Customers within this industry have the most dynamic machining needs as many designs change yearly. They’re also the most demanding production variety—which we enjoy, as it helps us continually improve our skills.

Visit our Contact page if you have questions about our machining capabilities.